I decided that I wanted to 3D print the main body components so that they'd be relatively lightweight, and it would also let me do non-2D geometries (as much as I love laser cutters and waterjets, I think I eventually get sick of being stuck in 2D). I based the design on 6mm carbon fiber squaretube, since it's very lightweight but still plenty strong enough for a small quadrotor. I also wanted to try out the relatively new KK2 flight control board, so I designed my body specifically to accommodate it (3mm holes spaced on a 45mm square).

I added slots for a velcro strap on the bottom side, to hold the battery. The holes for the control board also retain the squaretube arms, which fit into the square slots on the corners. I also split the model in half across the horizontal mid plane, in order to make it much easier to 3D print.

I wanted to get a head start on picking out components to I order them from China, because shipping takes forever. Here are some links to the major components:

- Motors: 2300 Kv

- ESCs (electronic speed controllers): max 18A continuous

- Battery: 1300mAh, 2S1P

- Propellers: 6x3

- Power distribution board

- Radio receiver

I decided to use the same radio transmitter that I already had for Derpcopter, there wasn't really any reason for me to buy another one. I also picked out substantially bigger ESCs than I needed, really the motors could run on ESCs half that size, but I was considering that I might want to bump up the motor size later, which I can with large ESCs.

I went ahead and ordered two sets of parts (one for me, one for a friend), then worked on the design (and my scooter!) for a few weeks while I waited for them to come. Now that I knew which motors I'd be getting, I went ahead and designed mounts for them which also serve as feet for the copter.

I also wanted a sort of dome structure on the top of the body, which would serve both to protect the control board and mount the radio receiver (mostly just make the quadrotor look more legit, though). I didn't have a very concrete idea of what I wanted the design to look like, though, so I just sketched out a few different designs until I came up with one that I liked.

I went ahead and printed out the frame parts while I waited on my electronics to arrive.

|

| Yay printers! |

I included my old radio transmitter for completeness, the orange and black one you see is the one my friend got for his quadrotor. Also, notice the extra props: I've learned a bit of a lesson there. New quadrotor = broken props, so buy extra.

I began by cutting my 75cm carbon fiber tube into 4 17cm sections. I also took rather meticulous photos of this whole build, because I'm planning on writing a quadrotor Instructable. Oh, and there happened to be a lightbox sitting at MITERS, the owners of which kindly decided to let me use it to take some pictures of quadrotor parts.

|

| I think you're supposed to wear a mask when you do this? Not much dust came up though. I think I held my breath. |

|

| Ooh, fancy. |

I arranged the arms and base together so that I could drill out the holes in the arms.

|

| Sorry it's a little hard to distinguish the white base from the white background, this is why I'm an engineer and not a photographer |

I then did essentially the same thing with the motor mounts, except I taped around them a bit to help hold them in place on the arm.

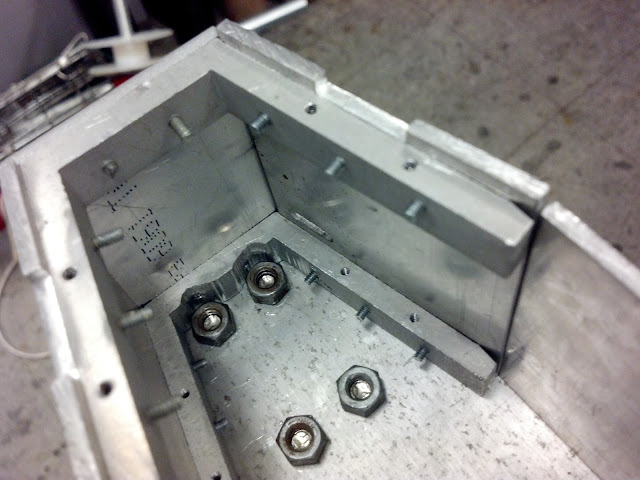

That done, my basic frame was complete!

|

| This one didn't quite fit in the lightbox :( |

|

| So pretty! |

Next, I discovered my first major mistake: I'd assumed that the motors used the same 3mm screw size as the control board, but actually the holes are for 2mm screws. Oh well, I didn't have the patience to do this the 'right' way and buy some screws from Amazon, so I just removed the motor mounts and drilled the holes out to 3mm.

|

| These are annoying to fixture properly and the alloy is so soft that I just decided to beast it with vice grips. |

|

| It's starting to look pretty quadrotor-y! |

And a final picture of the finished copter, with battery, radio, and propellers attached:

I zip-tied the ESCs to the arms to clean up the wiring and prevent them from just swinging around in flight. You'll notice that the dome I designed isn't attached in this picture, this is due to the fact that I underestimated the thickness of the power distribution board when I was buying screws. The body screws I got are too short to go through everything and mount the dome, so currently I'm waiting on new screws ordered through Amazon in order to complete the body. Regardless, it's fully capable of flying without the dome, the purpose is mostly aesthetic. I did fly it for a minute or so around when I took that last picture, but it was 5am at that point and the copter was very difficult to control (due to the default PI gains of the flight control being set way too high, causing it to oscillate around whatever desired position I gave it), so I decided to call it a night.

The next day I worked out the PI (if you're not sure what this means, I recommend reading up on PID control on Wikipedia. Copters typically don't have need for the D component because it's highly affected by noise in the sensors, and it slows the system response which isn't very desirable) settings to get a much more stable copter, and came up with a name: I dubbed it the Blitzcopter, owing to how I'd completed the entire construction over the course of one manic night.

Okay, I'm not going to leave you waiting for the video any longer than that, so here it is:

Yay! The reason it's flying so loud is that I haven't yet gotten a chance to balance the propellers, which entails adding little bits of mass (i.e. tape) to the blades in order to move the center of mass of the propeller onto the rotational axis, greatly reducing the vibration of the motors.

I've also taken a couple of hard landings and snapped some of the printed motor mounts due to the impact, for now I've super-glued them back together but I'm going to be designing new sturdier mounts won't break as easily.